Welding power sources are a fundamental component in the welding process. There are various types available, each with their own set of advantages and disadvantages. In general, welding power sources can be categorized as either conventional or inverter based. While a conventional power source offers extreme reliability, an inverter power source offers power saving and portability. A modern inverter machine uses modern semiconductors to produce a high-frequency current suitable for welding.

Different types of power semiconductors are used in welding inverters including insulated-gate bipolar transistors (IGBTs), metal-oxide-semiconductor field-effect transistors (MOSFETs). Each design topology has different advantages and disadvantages. It is important to consider these factors when selecting the ideal welding power source for a particular application.

APS welding inverters are a reliable and efficient choice when it comes to welding. When comparing costs, APS inverters are competitively priced, and are an affordable option for those looking for a high-quality welding power source. By understanding the various types of welding power sources, semiconductors used in inverters, and different design topologies, one can choose the best welding power source for their specific needs.

> Welding is a process of joining two metals. To make a joint of two metals immense heat is required. This heat is created in the form of an electric arc. To create this arc a power source is required.

> Ever since the process of welding entered the engineering field there is continuous innovations in the field of welding power sources.

> The choice of a welding power source depends upon the process of welding. There are two types of welding power sources.

1.Constant Current Power Sources. – A constant current power source is used in MMAW and TIG welding processes. MMAW stands for manual metal arc welding. TIG stands for tungsten inert gas welding.

2.Constant Voltage Power Sources. – A constant voltage power source is used in MIG/MAG and SUBARC welding processes. MIG stands for metal inert gas welding. MAG stands for metal active gas welding. SUBARC stands for submerged arc welding.

> We may understand that welding can be carried out using 1.AC power source. 2.DC power source. The following are the types of welding power sources that can be differentiated based on value based parameters.

Advantages:

1. Very low initial investment.

2. Very easy to service and repair.

Disadvantage:

1. Very High No Load current.

2. There is no control of current. The current is fixed and varies depending on electrode and input supply.

3. Very inefficient and very low power factor.

4. Running costs are high.

5. Brute for of current and welding quality is poor.

6. Welding at low amperage is not possible.

7. Bulky equipment occupying large floor space and not portable.

8. TIG/Argon Welding is not possible.

9. Welding non ferrous materials not possible. Low weld deposition rates.

Note: Some machines have multiple tap outputs, thus current can be adjusted but in steps only.

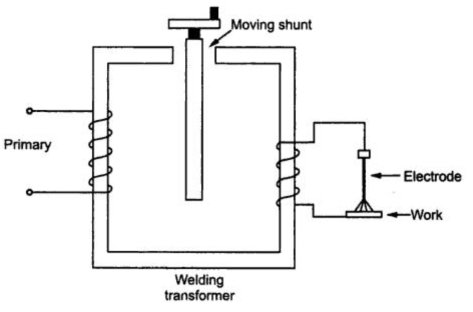

In this type of welding transformer, the central magnetic shunt can be adjusted. This adjusts the magnetic flux and hence output current gets changed.

Advantages:

1. Very low initial investment.

2. Very easy to service and repair.

Disadvantage:

1. Very High No Load current.

2. Very inefficient and very low power factor.

3. Current control is available but not satisfactory and precise.

4. Running costs are high.

5. Welding at low amperage is not possible.

6. Bulky equipment occupying large floor space and not portable.

7. TIG/Argon Welding is not possible.

8. Welding non ferrous materials not possible. Low weld deposition rates.

DC Power sources can be broadly classified in three types:

1. DIODE based Welding Rectifier

2. Thyristor controlled Welding Rectifier

3. Inverter based Welding Rectifier

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.