Our definition of the Industrial Internet or Industry 4.0 covers three aspects.

The fourth industrial revolution – characterized by the increasing digitization and interconnection of products, value chains, and business models – has arrived in the industrial sector. Our study, Industry 4.0 – Opportunities and Challenges of the Industrial Internet. It presents the essential attributes, opportunities, and challenges posed by this development. They estimate the share of investments in Industry 4.0 solutions will account for more than 50% of planned capital investments for the next five years. The first significant driver for the advance of Industrial Internet solutions lies in the opportunity to integrate and better manage horizontal and vertical value chains. Companies surveyed expect more than 18% higher productivity over the next five years. While today only one-fifth of the industrial companies have digitized their key processes along the value chain; in five years, 85% of companies will have implemented Industry 4.0 solutions in all important business divisions.

The digitization and interconnection of products and services (Internet of Things/Services) is a second important driver. It will contribute strongly to ensuring competitiveness and promises additional revenues of 2% to 3% per year on average. A third major driver is the newly emerging, often disruptive, digital business models that offer significant additional value to customers through tailor-made solutions. These new business models are characterized by a considerable increase of horizontal cooperation across the value chains, as well as the integrated use and analysis of data. They are therefore capable of better fulfilling customer requirements.

The various opportunities, the large extent of change, and the elevated need for investments make the Industrial Internet one of the most important topics for corporate management. However, the numerous challenges that the transition entails are also not to be underestimated. Besides the partly still unclear business cases for the Industrial Internet at the company level, industry standards have to be defined and agreed upon and questions need to be answered, for example, in the area of data protection.

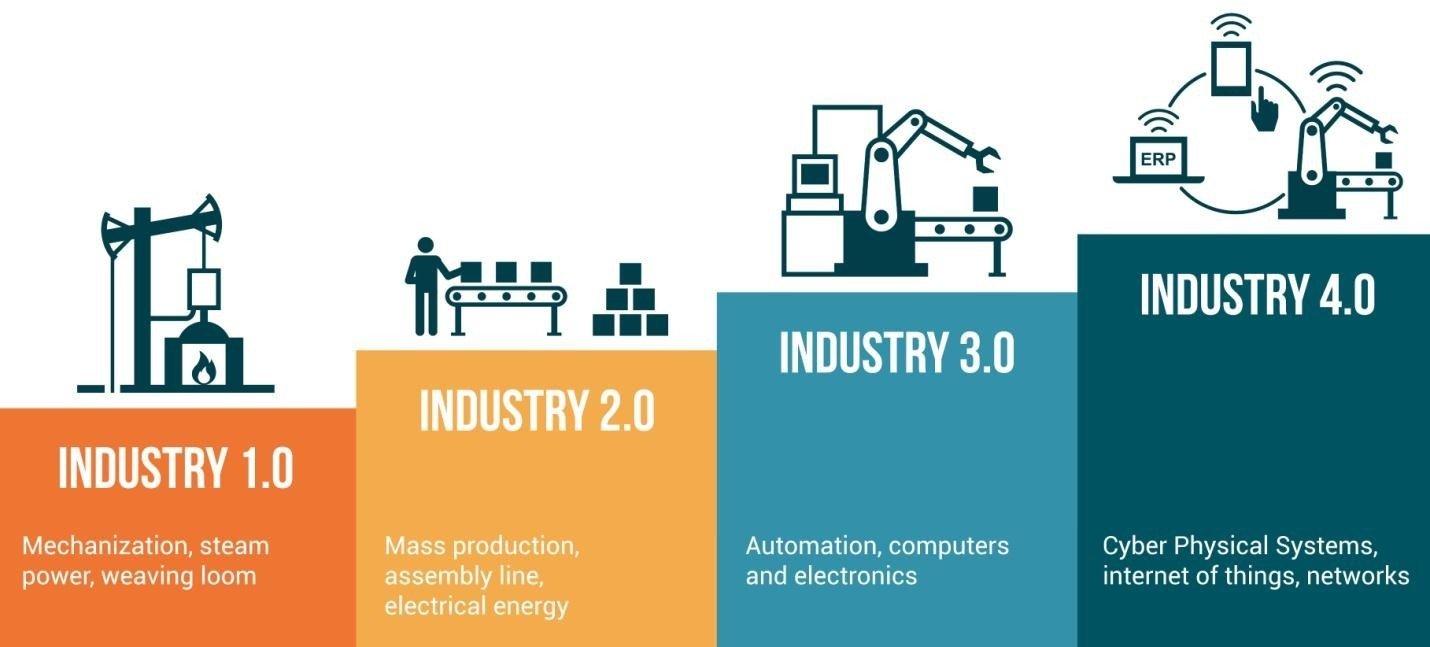

For centuries, goods including food, clothing, houses, and weaponry were manufactured by hand or with the help of work animals. By the beginning of the 19th century, though, manufacturing began to change dramatically with the introduction of Industry 1.0, and operations rapidly developed from there. Here is an overview of that evolution.

In the 1800s, water- and steam-powered machines were developed to aid workers. As production capabilities increased, the business also grew from individual cottage owners taking care of their own — and maybe their neighbours’ — needs to organizations with owners, managers, and employees serving customers.

By the beginning of the 20th century, electricity became the primary source of power. It was easier to use than water and steam and enabled businesses to concentrate power sources to individual machines. Eventually, machines were designed with their power sources, making them more portable.

This period also saw the development of several management programs that made it possible to increase the efficiency and effectiveness of manufacturing facilities. Division of labour, where each worker does a part of the total job, increases productivity. Mass production of goods using assembly lines became commonplace. American mechanical engineer Frederick Taylor introduced approaches to studying jobs to optimize worker and workplace methods.

Lastly, just-in-time and lean manufacturing principles further refined how manufacturing companies could improve their quality and output.

In the last few decades of the 20th century, the invention and manufacture of electronic devices, such as the transistor and, later, integrated circuit chips, made it possible to more fully automate individual machines to supplement or replace operators. This period also spawned the development of software systems to capitalize on the electronic hardware. Integrated systems, such as material requirements planning, were superseded by enterprise resource planning tools that enabled humans to plan, schedule, and track product flow through the factory. Pressure to reduce costs caused many manufacturers to move component and assembly operations to low-cost countries. The extended geographic dispersion resulted in the formalization of the concept of supply chain management.

In the 21st century, Industry 4.0 connects the Internet of Things (IoT) with manufacturing techniques to enable systems to share information, analyze it, and use it to guide intelligent actions. It also incorporates cutting-edge technologies including additive manufacturing, robotics, artificial intelligence and other cognitive technologies, advanced materials, and augmented reality, according to the article ―Industry 4.0 and Manufacturing Ecosystems by Deloitte University Press.

The development of new technology has been a primary driver of the movement to Industry 4.0. Some of the programs first developed during the later stages of the 20th century, such as manufacturing execution systems, shop floor control, and product life cycle management, were farsighted concepts that lacked the technology needed to make their complete implementation possible. Now, Industry 4.0 can help these programs reach their full potential.

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.